News and information

Operator ergonomics in focus for new control handle

In many industries, increasing ergonomic demands are placed on the lifting equipment handled by operators in manual material handling.

These requirements not only include guidelines on when a lifting aid is to be used – at what load and lifting frequency – but also factors such as the grip height and grip size of the actuator, starting forces at movements and range and access when picking up and delivering materials.

Lifts with precision

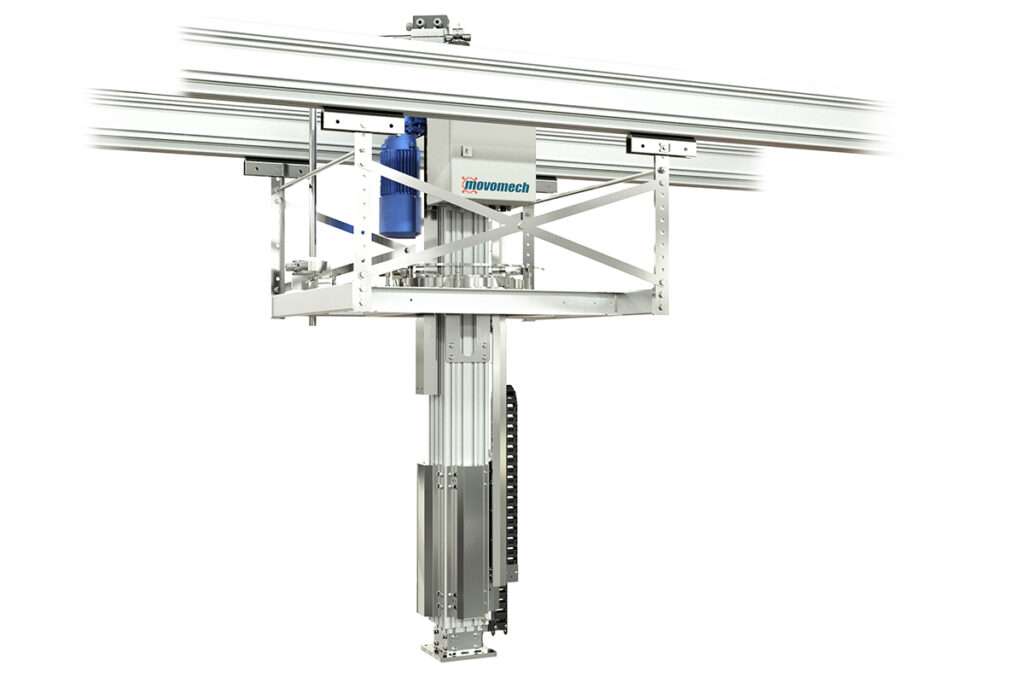

During the 1980s, Movomech developed the first version of the classic pillar lift manipulator Mechlift Pro™ – the universal lift manipulator which, thanks to its stable torque-absorbing structure, lifts heavy loads well beyond its attachment point; up to 1500 Nm in standard design. The operating has always been frequency controlled with joystick, enabling an accelerating lifting movement for an optimal precision during assembly and production processes.

Over the past 30 years, Mechlift Pro™ has been further developed and the lifter is now delivered in a total of 7 load classes, and in addition in two fully pneumatic versions.

During the 1980s, Movomech developed the first version of the classic pillar lift manipulator Mechlift Pro™.

New version of control handle

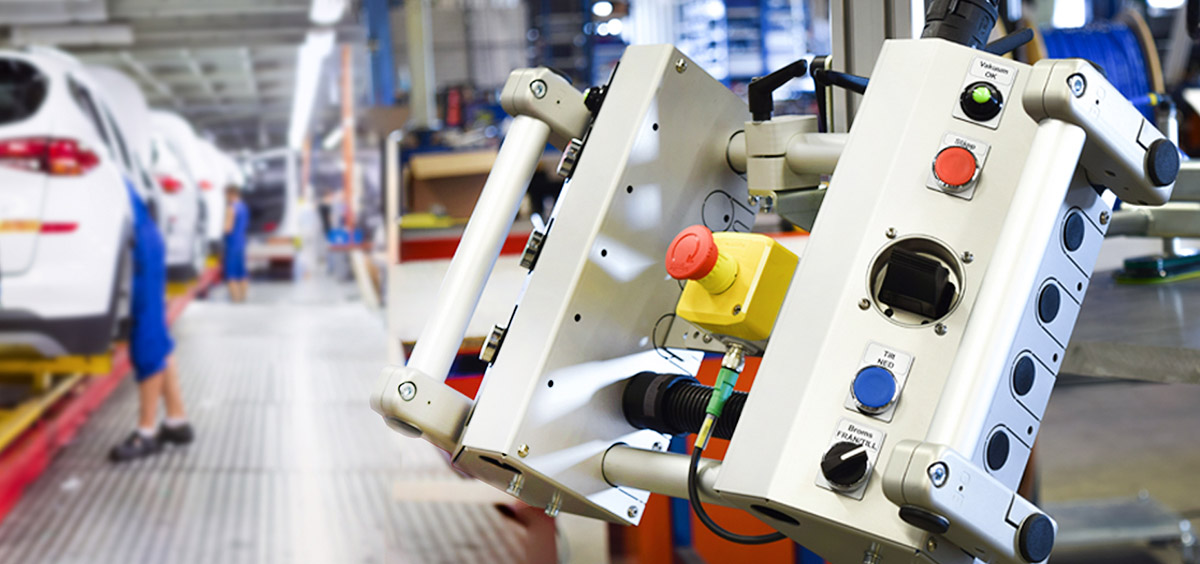

Focusing on operator ergonomics and customization, Movomech has now developed a new version of control handle for the industrial manipulator Mechlift Pro™.

The new control handle is completely modular in its design and offers generously with options in the form of joysticks, button controls and visual signal indicators to be easily adapted to each specific lifting operation.

Factors such as stability, individual adjustment possibilities, safety, correct grip angles and tested dimensions with regard to user percentiles are integrated in the design, while the user interface is intuitive to minimize learning time and work well at workstations with work rotation.

Developed with ergonomists

The handle has been developed and evaluated in collaboration with ergonomists in the automotive industry to ensure correct adjustment possibilities and general dimensions, but also an optimal positioning and angle of button controls and joysticks for lifting movement and for the option of x/y drive units.

The new handle concept’s modular design also offers the advantage that its delivery time matches the lifting manipulator and does not add any extra project time.

Operator ergonomics is in focus for new control handle

For more information on the Mechlift Pro™ lift manipulator and the new control handle, please contact Emil Lindell, Movomech AB.

Svenska

Svenska

Deutsch

Deutsch

Français

Français